Compact ATEX tube light / machine light | 230V - 110V - 42V - 24V - 12V

The extremely compact, explosion-proof LED tube and machine light is defined as a first-class solution for effective lighting in demanding environments. Their small space requirement makes them particularly suitable for illuminating confined areas, containers and machines where modern and long-lasting lighting is essential. At the same time, it meets all safety requirements with regard to explosion protection in an exemplary manner.

Safe light with compact dimensions

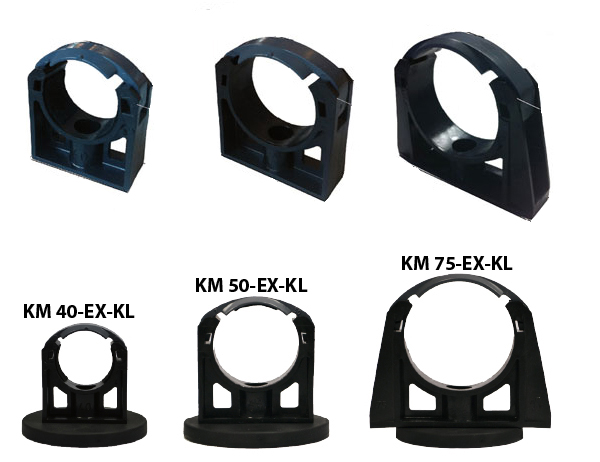

With three integrated POWER LED modules, this innovative light sets standards in terms of lighting quality. These ensure optimal illumination that is specifically tailored to the requirements of industrial environments. Safe light in vulnerable areas. Quick and uncomplicated installation is ensured by the fastening clips included in the scope of delivery, which enables time-saving installation. This practice-oriented solution makes the ATEX LED tube light particularly user-friendly and efficient to use.

Reliable light in harsh environments

An additional highlight is the protection class IP68, which makes the light dust and waterproof. This feature greatly expands their range of uses and makes them an ideal choice for environments where dust and moisture are a challenge.

Five voltage variants - can be used flexibly

In addition, the explosion-proof tube light is available in five different voltage versions, which enables flexible adaptation to different requirements.

Different color variants available

Upon request, we can equip the light with a colored cover in green, yellow, red, or blue. This instantly transforms the EX tube light into a signal or warning light, providing clear visual cues and further increasing safety and organization in the work environment.

Signal light: Color variants optionally available

Overall, the KE-LED-EX 4003 LED tube and machine light presents itself as a versatile, powerful and safe lighting solution for industrial use. Their compact design, combined with first-class safety features and user-friendly installation, make them an indispensable tool in environments where the highest standards are required. With protection class IP68 and various voltage variants, this light underlines its versatility and flexibility to meet a wide range of requirements.

other models: KE-LED-EX 3010 | KE-LED-EX 4006 | KE-LED-EX 5018 | KE-LED-EX 5024

ATEX Identification

| II 2 G | Ex eb mb op is IIC T4 Gb | | | Tool group: II | | | Hazardous zone: 1 and 2, 21 and 22 | |

| II 2 D | Ex tb op is IIIC T105° Db | | | Category: 2G and 2D | | | Temperature class T4 |

Highlights

- ex-proof tube luminaire with 3 POWER LEDs / 6500K

- Protection tube: polycarbonate, shock-resistant, 40mm diameter

- End cap: aluminium, black anodized

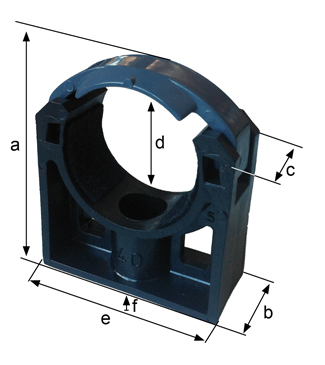

- Fixation: incl. 2 fixing clamps made of plastic

- Protection category: IP68 - 50m/5h (dust- and waterproof)

- Protection class: II / III

- Cable standard version: 10m H07BQ-F 2 x 1,5 mm² (extendable in 5 m steps)

- Standard version without plug, Ex plug (ATX, CEAG) available on request

- Available in the voltage versions: 230 Volt / 110 Volt / 42 Volt / 24 Volt / 12 Volt

- Special requests - as covered by our Ex-certificaton - can be fulfilled.

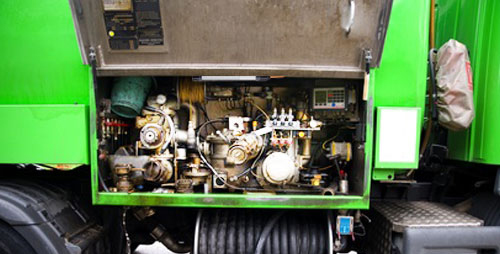

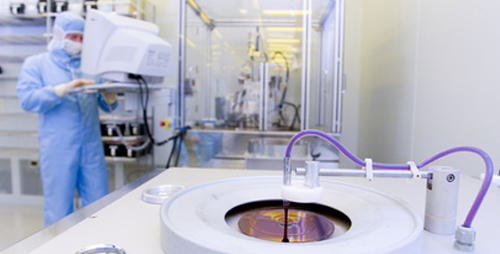

Areas of application

English (UK)

English (UK)  German (DE)

German (DE)