Omnidirectional EX inspection light | 230 volts & 24 volts

Optimal view in 360°

The KE-LED-EX 5018 impresses with 18 power LEDs, which create glare-free lighting through a diffuser film. With its 360 degree illumination, this light offers optimal visibility in every direction to perfectly illuminate your work area.

Robust, waterproof and safe

This robust inspection light is not only waterproof, but also safe for use in EX zones 1, 2, 21 and 22. Perfect for demanding environments such as tank and silo cleaning. The low weight of the KE-LED-EX 5018 makes transport and handling easier.

Protective extra-low voltage for safe use

Thanks to its protective extra-low voltage of 24V, the light can be used without hesitation. It offers a reliable and long-lasting lighting solution for potentially explosive areas and impresses with its high performance and robust construction.

Long lifespan and cost-effectiveness

With modern LED technology, the KE-LED-EX 5018 guarantees a long service life, which saves costs and time in maintenance tasks. Rely on their outstanding quality and reliability to ensure a safe working environment and optimal visibility.

Optional protective film for additional protection

Use the optional protective film to protect the protective tube from contamination. This makes the KE-LED-EX 5018 even more versatile and adaptable to different working conditions.

Tubular light with silo suspension for flexible use

Alternatively, the inspection light is also available as an omnidirectional, explosion-proof LED tube light, in conjunction with a silo suspension. This means that the light can be installed on the cable in tank and silo systems for inspection work. The cable lengths can be adjusted according to customer requirements to ensure optimal flexibility.

Invest in quality, safety and efficiency - the KE-LED-EX 5018 is the ideal inspection light for your demanding tasks in potentially explosive areas. Find out for yourself how it can improve your work environment!uality of this inspection light!

other models: KE-LED-EX 4003 | KE-LED-EX 4006 | KE-LED-EX 5024

ATEX Kennzeichnung

| II 2 G | Ex eb mb op is IIC T4 Gb | | | Gerätegruppe: II | | | Gefahrenzonen: 1 und 2, 21 und 22 | |

| II 2 D | Ex tb op is IIIC T105° Db | | | Kategorie: 2G und 2D | | | Temperaturklasse T4 |

Highlights

- ex-proof LED hand lamp with 18 POWER LEDs / 6500K

- 360° illumination

- Short switch-on time / long service life / low energy consumption

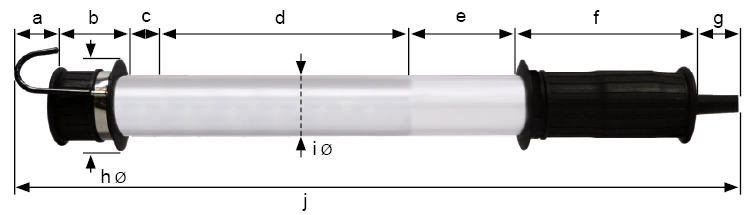

- Impact-resistant protective tube made of polycarbonate, 50mm diameter

- Glare-free light thanks to the integrated diffuser film

- Durable neoprene handle with a pleasant feel

- Plasticized, rotatable metal suspension hook

- Protection category: IP68 - 50m/5h (dust- and waterproof)

- Cable standard version: 10m H07RN-F 2 x 1,0 mm² (extendable in 5 m steps)

- Standard version without plug, Ex plug (ATX, CEAG) available on request

- Voltage variant: 230 volts / 24 volts

- Special requests - as covered by our Ex-certification - can be fulfilled

- KIRA explosion proof LED hand lamps (leadlamps) for safe use in the areas: Sewage treatment plants, sewer inspection, electricity providers, mills, biogas plants, gas stations, tank automotive, aerospace industry, aircraft maintenance & inspection, oil rigs, offshore, shipyards, THW, EX-zones, explosive dust and gas atmospheres, gas interference, crafts, food industry, chemical industry, petrochemical industry.

Areas of application

English (UK)

English (UK)  German (DE)

German (DE)