LED tube light, explosion-proof, 360° illumination | 230 volts & 24 volts

The ATEX LED tube and work light KE-LED-EX 5018 presents itself as a groundbreaking solution for comprehensive 360° illumination, perfect for working in explosion-proof areas (EX zones 1, 2, 21 & 22). This innovative light not only enables all-round illumination, but also offers flexible accessories that open up both fixed and temporary mounting options. With its versatility, the 360° light is ideal for mobile applications, especially in conjunction with the optional silo suspension, which makes it ideal for tank and silo cleaning work.

Homogeneous & glare-free work light

The integrated diffuser film of this lamp ensures that the light generated is glare-free and homogeneous, which makes the working environment particularly pleasant. This feature is particularly advantageous in situations where a clear view and precise illumination are crucial.

Robust and reliable

The robust construction of the ATEX LED work light not only ensures reliable performance, but also excellent protection against moisture and moisture. With the impressive IP68 protection rating, the luminaire is ideally equipped to function optimally in wet and damp work areas. This makes them a reliable choice in environments where working conditions are particularly demanding.

Flexible customizable

Another highlight is the possibility of individually configuring the supply cable length according to customer requirements. This flexibility makes it possible to adapt the luminaire precisely to the specific requirements and conditions of the working environment.

Overall, the ATEX LED tube light KE-LED-EX 5018 presents itself as an innovative and highly functional solution for lighting in explosion-proof areas. With its 360° illumination, the optionally available silo suspension, the glare-free lighting, the robust design for wet work areas and the individual configuration option, this light sets new standards in terms of efficiency, safety and adaptability.

alternatively available: EX version hand lamp KE-LED-EX 5018 hand lamp

other models: KE-LED-EX 3010 | KE-LED-EX 4003 | KE-LED-EX 4006 | KE-LED-EX 5024

ATEX Identification

| II 2 G | Ex eb mb op is IIC T4 Gb | | | Tool group: II | | | Hazardous zone: 1 and 2, 21 and 22 | |

| II 2 D | Ex tb op is IIIC T105° Db | | | Category: 2G and 2D | | | Temperature class T4 |

Highlights

- ex-proof LED hand lamp with 18 POWER LEDs / 6500K

- 360° illumination

- Short switch-on time / long service life / low energy consumption

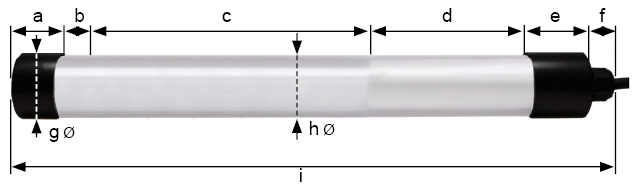

- Impact-resistant protective tube made of polycarbonate, 50mm diameter

- Glare-free light thanks to the integrated diffuser film

- End cap: aluminium, black anodized

- Protection category: IP68 - 50m/5h (dust- and waterproof)

- Cable standard version: 10m H07BQ-F 2 x 1,5 mm² (extendable in 5 m steps)st extendable)

- Standard version without plug, Ex plug (ATX, CEAG) available on request

- Voltage: 230V / 24V

- Special requests - as covered by our Ex-certificaton - can be fulfilled.

-

Special requests - as covered by our Ex-certification - can be fulfilled

KIRA explosion proof LED tube luminaires for safe use in the areas: Sewage treatment plants, sewer inspection, electricity providers, mills, biogas plants, gas stations, tank automotive, aerospace industry, aircraft maintenance & inspection, oil rigs, offshore, shipyards, THW, EX-zones, explosive dust and gas atmospheres, gas interference, crafts, food industry, chemical industry, petrochemical industry

Areas of application

English (UK)

English (UK)  German (DE)

German (DE)